I will have to chat with Doug about spring specs to determine.... they do have pretty fast ramp rates and i don't believe in running more seat pressure than you need to because of the possibliliy of compressing the hydro lifter.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doing it Gangsta

- Thread starter jwlandry

- Start date

jwlandry

Active member

At what rpm, boost psi, and how much lift will these springs handle?

Lift is good to 600

Boost.... whatever makes you happy

From the spec rpm will be good to 7000

juniort444e

New member

7000.... Matt can you tune my truck to 7000. Jkn but thats crazy RPM's

jwlandry

Active member

I will have to chat with Doug about spring specs to determine.... they do have pretty fast ramp rates and i don't believe in running more seat pressure than you need to because of the possibliliy of compressing the hydro lifter.

Let me know what come about that convo but since a 7.3 lifter is similar to a 6.0, and a 6.0 will turn 5k rpm and those have to open 2 valves vs. the 1 valve on a 7.3, dont see how it could compress it.

PowerstrokeJunkie

Active member

Youre rockers are going to hate life. That is if you go that far and keep stock ones

jwlandry

Active member

Youre rockers are going to hate life. That is if you go that far and keep stock ones

decisions decisions decisions:joy:

juniort444e

New member

What, or who makes a good rocker to replace the 7.3 stockers.

6.0dirtworker

Active member

This is snowballing into some serious cash blowing.

G Racing

New member

I will have to chat with Doug about spring specs to determine.... they do have pretty fast ramp rates and i don't believe in running more seat pressure than you need to because of the possibliliy of compressing the hydro lifter.

What mods will have to be done to the head to run these springs? are the push rods shorter to compensate for the taller spring? what seat pressure will these run closed and open?

jwlandry

Active member

What mods will have to be done to the head to run these springs? are the push rods shorter to compensate for the taller spring? what seat pressure will these run closed and open?

I know it was directed at Matt but i can answer those:

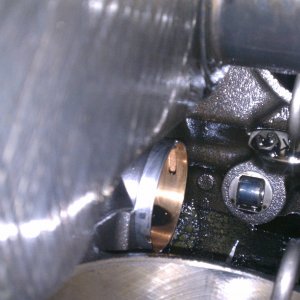

No mods need to be done to the heads to run them. Even though the spring is taller the valve is still the same height so, so are the push rods and they are 175 closed and 425 fully open.

jwlandry

Active member

As far as i know, No.

uncool

New member

At 175 on the seat? Bit much don't ya think?

juniort444e

New member

Well the cam i am going with needs 150, so 175 doesnt sound over kill. For anything else i would think so.

Big Bore

Active member

At 175 on the seat? Bit much don't ya think?

What I was thinking. Stock seat pressure under boost is around 50psi worst case. Even with 75psi of boost, thats still 100psi of seat pressure on the Go-Go springs. And I see the bigger spring retainers, but what does this do to the valves/stems/seats etc? Comp has a step up from the 910's that had all the seat pressure I figured I needed for 65psi of boost. These sound like a good way to break other parts. However I'm open to being educated.

juniort444e

New member

What I was thinking. Stock seat pressure under boost is around 50psi worst case. Even with 75psi of boost, thats still 100psi of seat pressure on the Go-Go springs. And I see the bigger spring retainers, but what does this do to the valves/stems/seats etc? Comp has a step up from the 910's that had all the seat pressure I figured I needed for 65psi of boost. These sound like a good way to break other parts. However I'm open to being educated.

I was always under the impression that boost wasnt the only thing that effected it. Like i stated, im going with a stage 2 cam that requires a higher seat pressure so these sound like a go for me. But im not sure on all the specs with everything else.

uncool

New member

Well the cam i am going with needs 150, so 175 doesnt sound over kill. For anything else i would think so.

Why does the cam you are getting need 150 lbs on the seat? Is it because someone told you so?

These things are not 7500 RPM small blocks with solid roller cams.

Please educate me on why.

I understand the need for a better spring.

This has nothing to do with bashing or questioning the guy who had them made.

If there was a radical, small base circle, full custom brand new cam that would make power at some astronomical Rpm that we can't even fuel at with the HUEI, then sign me up for them.

Until then, 910's or the 26918's work fine.

The ramp rates on the stage II cam specd by Matt are the reason for the higher spring rate. But I do not agree with the idea that if 150 is what is needed then 175 is some how ok or better. Whether that ends up being the case or not that is flawed thinking. The higher the spring rate the faster the wear rate. Not to mention it takes more energy and friction so unless their some positive return..... .

How exactly are you guys coming up with a 92 and 72 pound seat pressure for the 910 and OEM respectively?

I think making the assumption that if 150 is the needed seat pressure for a cam that more or 175 would some how be better as a general process of reason is flawed. More seat pressure than needed equals excessive wear, increased friction and energy expense. What is the real world gain to be had to offset the cost? What does going from 150 to 175 get you? 7K with HUEI when our injections system with current openly fielded parts has barely broken 4K

How exactly are you guys coming up with a 92 and 72 pound seat pressure for the 910 and OEM respectively?

I think making the assumption that if 150 is the needed seat pressure for a cam that more or 175 would some how be better as a general process of reason is flawed. More seat pressure than needed equals excessive wear, increased friction and energy expense. What is the real world gain to be had to offset the cost? What does going from 150 to 175 get you? 7K with HUEI when our injections system with current openly fielded parts has barely broken 4K

Last edited:

juniort444e

New member

I just simply stated that i didnt think they would be over kill for that cam. Maybe they are, thats what im trying to figure out. I have 910's with shims now and they are not going to be enough, and they way im looking at this is, if i cant get a spring to match the cam perfectly then why go less with seat pressure. Less seat pressure i presume would be worse then getting more seat pressure if the cam calls for xxx amount and i cant meet that. And with live tuning i dont see how or why these setups couldnt hit 4k rpm and still have a decent amount of power.

Im learning here so teach me. But i still dont see how 25lbs extra will hurt that much if at all any with the right parts.

Im learning here so teach me. But i still dont see how 25lbs extra will hurt that much if at all any with the right parts.