Powerstroke Cowboy

Well-known member

Since I obviously cannot know exactly where you might be getting hung up, I'll try to explain everything in detail, simply ignore the parts you have a firm grasp on.

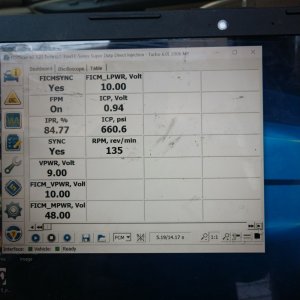

12psig (psi gauge) is 26.7psia (psi absolute), 12psi + 14.7psi of atmosphere. Since the gauge is set to zero at 14.7psi, a reading of 12 tells us we actually have 26.7psi.

This represents a pressure ratio across that compressor of 1.8163:1, 26.7psia / 14.7psia. The meaning of this is that the compressor is taking in air at 14.7psia and compressing it 1.8163 times such that it is discharging air at a pressure of 26.7psia. That is the pressure ratio. It is technically described as P2/P1 where P2 is the outgoing and P1 the incoming pressure.

From here the easiest way to see this might be to simply take a ride through the system.

The first stage takes in air at 14.7psia at sea level. If it's producing a pressure ratio of 1.8163, then it is compressing that air from 14.7psia to 26.7psia on it's outlet.

The second stage compressor then takes in this air at 26.7psia and compresses it another 1.8163 times such that it takes the air from 26.7psia and compresses it to 48.5psia.

The third stage compressor then takes in this air at 48.5psia and compresses it yet another 1.8163 times, such that it takes in the air at 48.5psia and compresses it to 88.08psia.

And with 3 total stages, each running a pressure ratio of 1.8163:1 and starting at 14.7psi, 88.08psi is exactly what you will end up with.

Converting back to gauge pressure, our boost gauge would read out 73.38psi (88.08psia - 14.7psia worth of atmosphere).

I hope that does it.

This does it Charles!!!! THANKS!!!!!!

Now I think I get the hole picture. I was figuring the first stage right, just not the last two.

Thank you sir.. you just made my day!!!

So when are you going to start the new project dustin!!! I realy think you should. you would even have a quicker spool up then the stock turbos could give.

I think this might be a cheaper rought then even the tow powers from elite!! Well ALMOST. But you would flow more air and still have the Quicker spool up.