I have an 02 crew cab now and wanted to update this thread since this truck is damn near stock and needed a set of injectors to replace the tired set that came in it when I bought it.

This truck is simply my Daily driver that took over for my red truck when I needed two more doors to house a couple car seats in the back that my regular cab could not support. The injectors that came in this truck would not start on a cold day, just flat worn out injectors.

So....

When I replaced them who thinks I went with an AD or something with a tiny little nozze?

I took my old 300's and put a 200 EDM on them. The truck had some crap intake and a 4" downpipe, otherwise it was 100% stock. Since I had a 38R handy I threw it on when I did the injectors. The 38R has the 1.15 non-gated housing.

The truck is super zippy. I forgot how easy it is for a stock compression truck to zip around. I've pushed into the stock trans as far as I can basically. No 30% truck on planet earth would touch it. The 30% truck would be rolling massive coal and losing ground while this truck was leaving out perfectly clean.

I have no gauges, don't need any. I have no fuel pump changes, no oil system changes, nothing. The air filter is as it came, full of dirt, bugs and pinestraw needles. Doesn't matter.

If I had a stock charger I would simply lower the pw a bit to keep it under 25lbs on the top end.

When it comes to tuning it was dead on. I messed around with the auto pcm at first until I realized the surging was because it was not connected to the trans anymore. When I switched to the AEB man trans pcm I sh*t you not, the FIRST program I wrote, and bare in mind this is from DEAD SCRATCH because I did not even have a single file for that cache code, so this includes shaping all the scalers and working through all the parameters from SCRATCH..... regardless, it went down the road GREAT! ZERO, I mean ZEEEEEERO smoke. Flat to the floor 1500rpm kind of zero smoke. And it was WAAAAAAAY too strong. It's not like it was a limp noodle program, this thing was trying to break the trans like right now. On wet roads I had no traction at any speed up to around 100 or so where I gave up. That's on a 35" nitto. So it was making power, too much. But ZERO smoke.

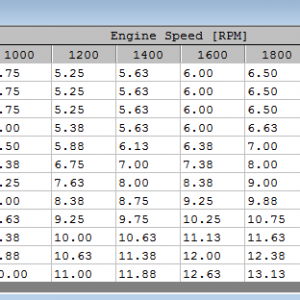

It's not rocket science. I maxed the pw at ~2.2, ran 3000 psi oil and had a nice MFD table that was smooth and linear. I have since dropped the max pw to around 2 IIRC so I don't break the trans. I also added in the little bs like killing the overboost and stuff so you don't need to trick the MAP sensor.

Anyway, point being, I never even sat in the truck and wrote a file that went down the street like a boss right out of the gate.

Anybody that has problems with a 200 do me a favor and check your pulsewidth. Driving around at part throttle in OD lets say, and lugging down, you need to be like 1.x, like 1.2, 1.4 or so.

I don't know what's happening for you all that seem to struggle with a larger nozzle, but pw is all I can think of for you to check, because I can't MAKE a 200 not work!!!

Best....... nozzle....... ever......

On Edit:

Truck seriously just has an intake, exhaust, 38R and 300/200's. Trans has a PCS simply because the Ford PCM is a joke for the auto. Screw oil, fuel lines, filters, pumps and all bs. Not needed.

Life's a lot simpler than we often make it. You could take a bone stock truck and add absolutely nothing but the 300/200's and zip around town all day long with 20,000lbs behind you smoke free, leaving most people with everything known to man under the hood in your dust because they can't seem to control one value.... pulsewidth....