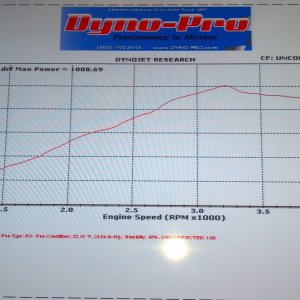

As one commented. They rebuild every pass. The high load of a 800 hp diesel compared to a 8000hp small block is a bit different. They are not worried about piston jets cooling the cylinder walls either. AND there clearance tolerances are alittle bigger to accommodate for such high weight oil and the extreme heat they run. Where we are worried about 250*F. They are seeing in excess of 350*F fast and In a hurry. So there oil is getting close to a flash point if they don't knock it off soon. 70w oil at 350-400*F Flows like water.

The engine design from a drag car to this 6.7L isn't a fair comparison at all.

I was thinking the mechanics of rod and main bearing lubrication was a direct comparison. If other oiling considerations in a diesel engine limit your options than so be it. I dunno.

Forget the top fuel comparison. Why does Ford require my Shelby to run 5w-50 but a dedicated drag truck under much more stress would be fine with 0w-30? If it is as you said, "Thick oil provides much less protection in high speed moving parts than thin oil. Thin oil is leaving the designed space between the bearing and journal with enough room to allow the nicely heated oil molecules to roll properly", why does everything in the racing world seem to be the opposite logic regarding oils?