the fact is b code a code hybrids to go further they need more oil period or to use less of it. if you use a soleniod and spring that can handle higher ico without flotating/fluttering. That would give an all around jump in what can be done across the board but we still are stuck with pressure drop and actual hpop output as standard dual hpops will not keep up and a turned up gen III would likely be the best choice. But then you run into the issue that the lpop possibly even ds hv lpop can not keep up. The answer to all of this is drop the b

ratio. and use less oil vol As you can then runways higher ico you have an even broader resolution (quality) range for the injector as it can run now both ends further.

Add a larger nozzle which has already been done on a custom basis so you can have reliability with the 400+ nozzles. Now you could run up icp say to 4500+ .

By doing this you remove the issues of oil volume.

Personally I would go with a b code modded as I stated above. The only other thing I did not mention as I felt it was obvious is to machine the oil passages and poppet to minimize pressure drop ie best flow.

As i am no expert only pulling apart a few handfuls of injectors max there are other things that need to be addressed but to me those are the big ones.

* more powerful solenoid and spring allow for significantly higher icp

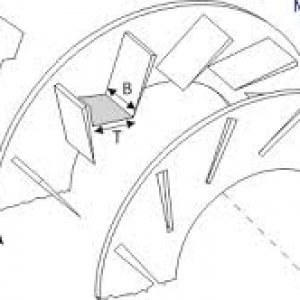

*.lower ratio barrel to plunger to decreaser oil vol needs

* oil passage poppet changes to minimize pressure drop across the injector.

* larger nozzle for increased durability

personally i think with those changes we may need acumulators on the oil rails to handle hammering but thats super easy add on so no biggie if it did arise with the higher icp and flow rates in and out of the injectors.