I may be trying a set this spring... Cant bash the product at this point, only the way the builder started out.

uh oh.....did I just read what I thought I read?

Where to buy, checked in the Px section and didn't see them there.

Sorry for the derail OP..

Feel free to give us a call or shoot me a PM!

What exactly is " new technology" here?

Changing the ratio is nothing new. The most common is the standard 7:1 and the hybrid 5:1. Higher has been tried, not proven beneficial as of yet and lower is being done now. Again, nothing ground breaking I hear as of yet.

If it isn't increasing injection pressure of the fuel or allowing for higher rpm capabilities (faster injection) then what is so special about them. I would like to know. Not bashing but no one seems to know or is wanting to explain just what they are.

6:1 injection ratio

finish on the plunger and barrels is about twice as hard as factory components.

Calculated injection pressure at the nozzle is really not something to be worried about, isn't it the speed of the fuel?

Recently I was asked for Sure Flow specs.

200 cc 100% nozzle

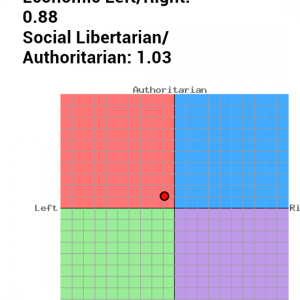

RPM====ICP====PW======CC

700--------500-------2.0-----------44

RPM====ICP====PW======CC

1700------800--------1.8-----------56

RPM====ICP====PW======CC

2000------2300-------2.5----------180

RPM====ICP====PW======CC

2000------3000-------2.5---------195

RPM====ICP====PW======CC

2200------3000-------3.0----------195

As rpm exceeded the injectors refill rate ,you start to see a reduction in cc's injected.

After 2300 rpm total flow begins to fall.

This flow is listed with out fuel side or oil side reaction time modifications.

The modifications carry injection farther into the rpm band. The next set of specs I post will be with the modifications.